Operating Principle

To continuously increase productivity during the working day in the field, an alternative or additional power take-off PTO on the agricultural tractor is often necessary. This may be because the main power take-off is already occupied by another implement, because an additional power point is required, because the power take-off needs to be located in another area of the tractor, or because the power take-off should rotate in the opposite direction.

A particularly versatile solution is the use of a hydraulic motor with a standard agricultural male splined output shaft (1-3/8" diameter with 6 splines).

This solution allows the user to have an additional and/or alternative power take-off. The hydraulic motor can be fed in several ways:

- Using the tractor's own hydraulic pump.

- Using the hydraulic pump of a hydraulic power unit with an internal combustion engine (gasoline or diesel).

- Through the hydraulic pump of a hydraulic power unit with an electric motor.

- Through a hydraulic pump connected to the tractor's main power take-off.

How to connect the hydraulic motor?

To rotate the motor's power take-off shaft, only the pressure and return hoses of the hydraulic system need to be connected to the hydraulic motor itself. If necessary, depending on the motor model, the motor's own drain hose must be connected.

The control of the rotational speed of the hydraulic motor's shaft is achieved by regulating the oil flow that reaches the pump. The hydraulic equipment can also be complemented by adding a flow regulator in the pressure line or on the motor itself. This allows the optimal rotation speed for the implement connected to the motor to be regulated. Such implements can include a seeder, a fertilizer spreader, a water pump, a log splitter, a shredder, etc.

Double Rotation Direction of the Power Take-Off

As mentioned earlier, this option is particularly versatile because, in addition to being able to precisely control the rotation speed, it also allows for easy reversal of the rotation direction. This aspect is important because there are implements that require the power take-off to rotate to the right and others to the left, and often the rotation direction of the implement is not compatible with that of the tractor's power take-off.

This functionality is achieved in several ways:

- The simplest is to swap the pressure and return hoses on the motor connections, as it is usually reversible.

- Another possibility is through a manual or electric hydraulic distributor mounted on the motor itself or in the hydraulic circuit.

- Using block and solenoid valves (usually with 12V DC coils).

The concept of changing the rotation direction of the power take-off is also suitable when, for example, you want to connect an implement that only allows rotation in a specific direction, such as water pumps or a turbine or fan. Most water pumps require the power take-off to rotate "to the left" and not "to the right". This peculiarity of water pumps often does not allow them to be directly connected to the conventional power take-off of the tractor.

Possibilities for Installing the Hydraulic Motor

Depending on the implement to be connected to the power take-off, it is often necessary for the output to be at 90 degrees or 180 degrees relative to the tractor's power take-off shaft. The hydraulic motor can be mounted in any direction to facilitate direct connection with the equipment/implement without the need for complicated cardan transmissions.

In turn, the height of the motor shaft or distance with respect to the equipment or implement to be connected can be easily varied by lengthening or shortening the flexible hoses of the hydraulic motor. This is important to consider often when the height or situation of the equipment/implement to be connected is difficult to access for the tractor.

How to Define Which Hydraulic Motor is Most Suitable for My Application?

The first basic point to define is what speed and power the implement that we want to connect to our new power take-off requires.

The second point is to check that the oil flow and pressure available are adequate for the speed and power required by the implement to be connected.

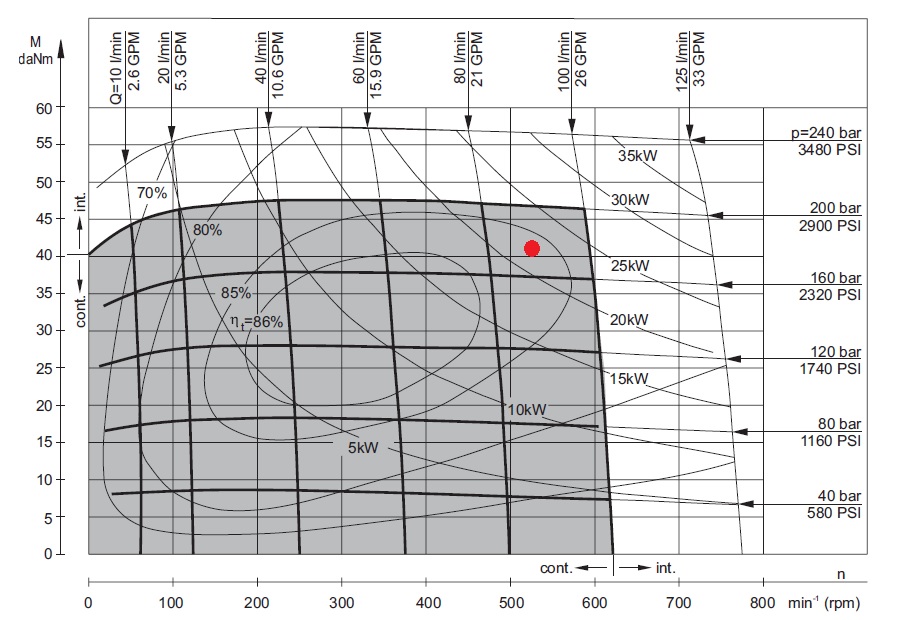

For example, if the implement we want to place on the new alternative power take-off requires that the motor shaft rotate at 540 rpm and supply a power of 30 HP (22 kW), we will need an available flow of at least 85-90 liters/minute and a pressure of 170-180 bar.

In the following graph, you can see the performance of a 160 cc/rev displacement hydraulic motor depending on the oil flow that reaches it and the pressure drop in the motor itself. Following the power and speed curves, it is observed that a pressure drop of 170-180 bar and a flow of about 85 liters/minute are needed to obtain a power of 22 kW (30 HP). See red point on the graph.

If the flow reaches the motor through the tractor itself, it is important to note that the flow required by the hydraulic motor must be able to flow smoothly without forcing or continuously maximizing the revolutions of the tractor's engine to avoid, among other negative aspects, excessive heating of the oil.

On the other hand, it will also be very important to ensure that the maximum available pressure and the flow that will reach the motor are always within the safety margins established by the motor's own design to avoid damaging it during operation. If necessary, a flow regulator valve and/or a pressure limiting valve should be installed.

Below you can click on the following link to see a list of our products suitable for working at 540 rpm as an alternative power take-off. Select the motor that best suits your needs based on the required power and then check that the flow and pressure available are suitable for that motor and implement to be connected to the motor shaft.

Hydraulic Motors for Use as Alternative Power Take-Offs:

We hope this information has been helpful. If you have any additional questions on this topic or any of the hydraulic systems or components we work with, please do not hesitate to contact our team, we will be delighted to assist you.

Create Date: 2023-12-23 21:50:00

Update date: 2024-08-21 09:00:00

SHIPPING WORLDWIDE

Let us assist you in choosing the perfect hydraulic component for your machine or upcoming project. We offer expedited shipping to anywhere in the world through top logistics companies such as DHL Express, TNT, FedEx or UPS.